摘要:

在(zai)(zai)玻(bo)璃(li)(li)(li)行業,稱(cheng)(cheng)重(zhong)(zhong)配(pei)料(liao)廣(guang)泛應用(yong)(yong)在(zai)(zai)平板(ban)玻(bo)璃(li)(li)(li)、日(ri)用(yong)(yong)玻(bo)璃(li)(li)(li)、玻(bo)璃(li)(li)(li)纖維等傳統領域(yu)。同(tong)時也使(shi)用(yong)(yong)到(dao)微(wei)晶玻(bo)璃(li)(li)(li)、光學(xue)玻(bo)璃(li)(li)(li)、電子玻(bo)璃(li)(li)(li)等特(te)殊(shu)玻(bo)璃(li)(li)(li)等生(sheng)產制造領域(yu)。稱(cheng)(cheng)重(zhong)(zhong)方式(shi):減量法配(pei)料(liao)、疊加(jia)配(pei)料(liao)、連續配(pei)料(liao)。使(shi)用(yong)(yong)方法:在(zai)(zai)原料(liao)的存儲、輸(shu)送、稱(cheng)(cheng)重(zhong)(zhong)配(pei)料(liao)、除塵等環節通過使(shi)用(yong)(yong)我公司生(sheng)產的稱(cheng)(cheng)重(zhong)(zhong)…

在玻(bo)(bo)璃(li)(li)(li)行(xing)業,稱重(zhong)配料廣泛(fan)應用在平板(ban)玻(bo)(bo)璃(li)(li)(li)、日(ri)用玻(bo)(bo)璃(li)(li)(li)、玻(bo)(bo)璃(li)(li)(li)纖(xian)維等(deng)傳統領域(yu)。同(tong)時也使用到微晶玻(bo)(bo)璃(li)(li)(li)、光學(xue)玻(bo)(bo)璃(li)(li)(li)、電子玻(bo)(bo)璃(li)(li)(li)等(deng)特殊玻(bo)(bo)璃(li)(li)(li)等(deng)生產制造領域(yu)。

稱重方式:減量法配(pei)料、疊(die)加配(pei)料、連(lian)續配(pei)料。

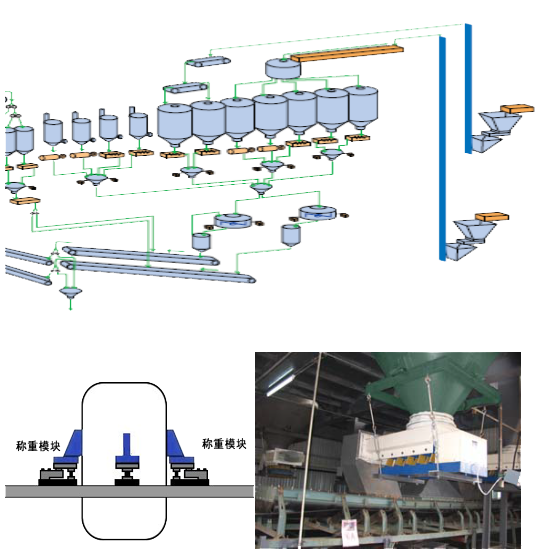

使(shi)(shi)用(yong)方法:在(zai)原料的(de)存(cun)儲、輸(shu)送、稱(cheng)重(zhong)(zhong)配料、除塵等環節通(tong)(tong)過(guo)使(shi)(shi)用(yong)我公司生(sheng)(sheng)產的(de)稱(cheng)重(zhong)(zhong)模塊(稱(cheng)重(zhong)(zhong)傳(chuan)感器)和稱(cheng)重(zhong)(zhong)儀表精確稱(cheng)量,再將稱(cheng)重(zhong)(zhong)數據通(tong)(tong)過(guo)通(tong)(tong)訊的(de)方式上(shang)傳(chuan)到PLC和公司ERP系統,實現整個工(gong)廠(chang)的(de)生(sheng)(sheng)產管理(li)和物(wu)流監控。不同(tong)工(gong)段的(de)數據相互比(bi)較(jiao)和核對,便于及時發(fa)現和解(jie)決生(sheng)(sheng)產管理(li)中產生(sheng)(sheng)的(de)問(wen)題(ti)。

該(gai)系統主要由現場儀表(稱(cheng)重傳感器(qi)、稱(cheng)量控制器(qi))、PLC與(yu)PC操作站以(yi)及(ji)與(yu)之配(pei)(pei)(pei)套的控制柜、操作臺和(硬)模擬屏(ping)等組成(cheng),能夠實(shi)現稱(cheng)量與(yu)配(pei)(pei)(pei)料、混(hun)合以(yi)及(ji)配(pei)(pei)(pei)合料輸送整個(ge)配(pei)(pei)(pei)料過(guo)程的自動控制。稱(cheng)重傳感器(qi)、稱(cheng)量儀表通(tong)過(guo)總線(Profibus)實(shi)現與(yu)PLC通(tong)訊。